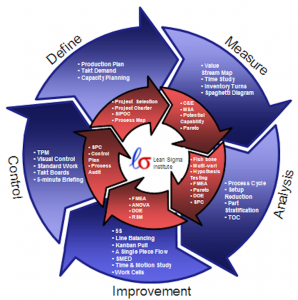

This section of the site is intended to be used a reference guide for the Six Sigma methodology. The material is organized into sections; each containing various aspects of the methodology. The information is indexed and searchable, hence it can be used as a tool during the various phases of any project by any team member to assist in Six Sigma concepts, phases (DMAIC/DMDAV – existing or new product development), formulas or activities across phases.

Six Sigma today is used across a wide range of industries like banking, business process outsourcing, telecommunications, insurance, construction, healthcare, and software. Many global companies like General Electric, Motorola, Allied Signal, Honeywell, Honda, Sony, Cannon, Polaroid, Texas Instruments and Whirlpool are using the Six Sigma methodology.

Six Sigma today is used across a wide range of industries like banking, business process outsourcing, telecommunications, insurance, construction, healthcare, and software. Many global companies like General Electric, Motorola, Allied Signal, Honeywell, Honda, Sony, Cannon, Polaroid, Texas Instruments and Whirlpool are using the Six Sigma methodology.

What is Six Sigma?

Six Sigma is a process based methodology for pursuing continuous improvement. Companies use this methodology to reduce defects in their processes.

Companies measure their performance by the sigma level of their business processes. Initially, companies accepted three or four performance levels as the standard. These processes created 6210 to 66,800 defects /per million opportunities. The sigma level of 3.4 defects per million opportunities is a reaction to increasing customer expectation and the fact that business processes and products are becoming increasingly complex and competitive.

The primary aim of Six Sigma is to focus on the customer first and then use facts and data based on customer requirements to get better results or improve the process. Thorough understanding of the process and the product drives the business and fulfils customers’ expectations.

Sigma, σ, is the Greek letter used to measure the variability in the process. Six Sigma stands for Six Standard Deviations from mean. Standard Deviation is a statistical method to define how much variation exists in a set of data or a process.

For example, a pizza home delivery company goes with a thumb rule of delivering a pizza within 30 minutes. In case the pizza delivery boy fails to deliver it within 30 minutes, the customer will get a 50% discount on his next purchase. (And it is considered as a defect on the part of the company.) If only 65% of the pizzas are delivered on time, the process will be at ‘level 2’ sigma. If 92% pizzas are delivered on time, the company’s performance is at ‘level 3’ sigma. If the company delivers 99.4% of the pizzas on time, the company’s perform ance is at ‘level 4’ sigma.

If the pizza company wants to be at ‘level 6’ sigma, it has to deliver pizzas within a level of 99.9997% accuracy. That means a process efficiency of 99.9997%.

| Service Area | Description |

|---|---|

| Content Authoring | Allow for the creation of tutorials, CBT courseware, web sites, CD-ROMs and other interactive programs |

| Content Review and Approval | Allow for the approval of interactive programs |

| Tagging and Aggregation | Support the identification of specific content within a larger set of content for collection and summarisation |

| Content Publishing and Delivery | Allow for the propagation of interactive programs |

| Syndication Management | Control and regulate an organizations' brand |

The sigma value of a business or a firm should always be high as it acts as a methodology that indicates the performance of the process. The measures used in Sigma primarily focus to perform defect-free-work. A defect may be described as customer dissatisfaction about anything.

Today Six Sigma is delivering business excellence, higher customer satisfaction, and superior profits by dramatically improving every process in an enterprise from financial to operational to production.